TOP MAGLOCK PROCESS

Plating on materials lighter than steel has been a goal of many industries for a long time. For the longest time Aluminum has been the go to for a lighter substrate but Magnesium is beginning to gain some traction. Magnesium is a desirable substrate to use due to its abundance as an element, and it is also has very good strength to weight ratio for many engineering projects.

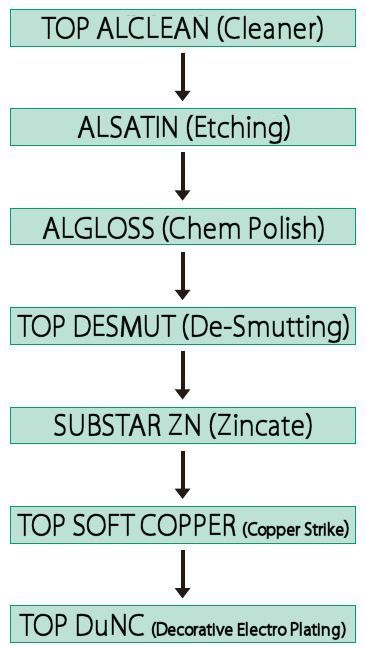

Plating Magnesium alloys and Magnesium castings is very important as they are very susceptible to corrosion over time. One of the difficulties of plating on Magnesium is that it is a highly re-active metal. It is so reactive that it can react with metal ions in the bath which will leave poor plating on the part. To solve many of the issues with plating on Magnesium we offer our Top Maglock Process. Designed specifically for Magnesium, our Maglock process is tailored from the cleaner to the Zincate we also offer a non cyanide copper strike and Chromic acid free etch for the pre-treatment before continuing with the plating process Please see the outline below:

For more information please contact us.