Total Process and Specialized Additives

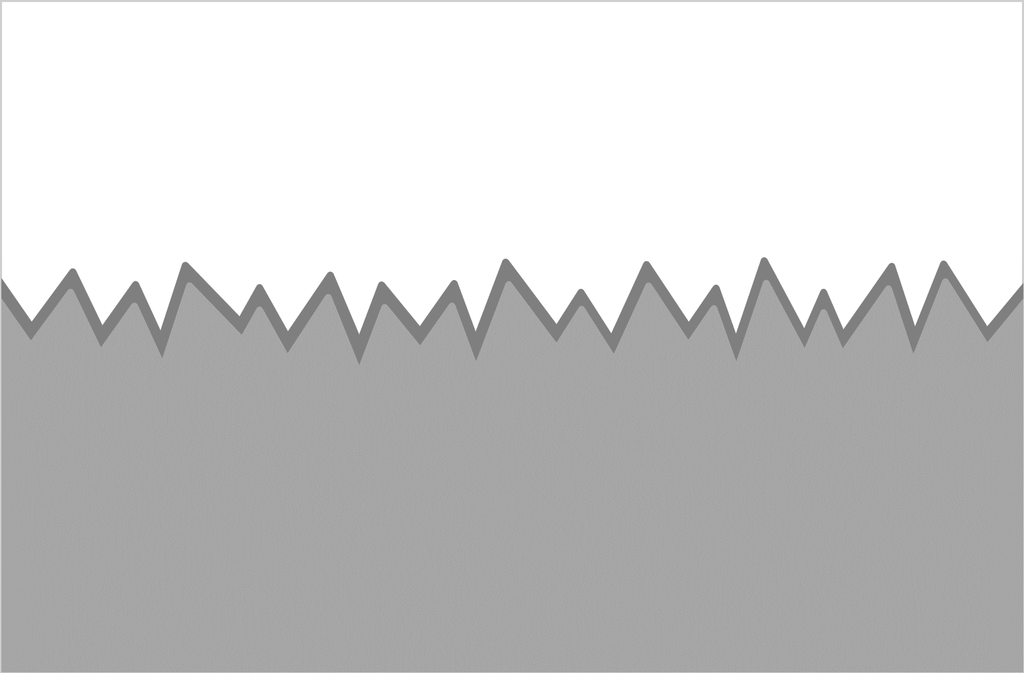

Etching:

Generally with sodium hydroxide solution, etch and remove the segregation layers and natural oxide films on the surface.

Products: ALSATIN SK, ALSATIN L, etc.

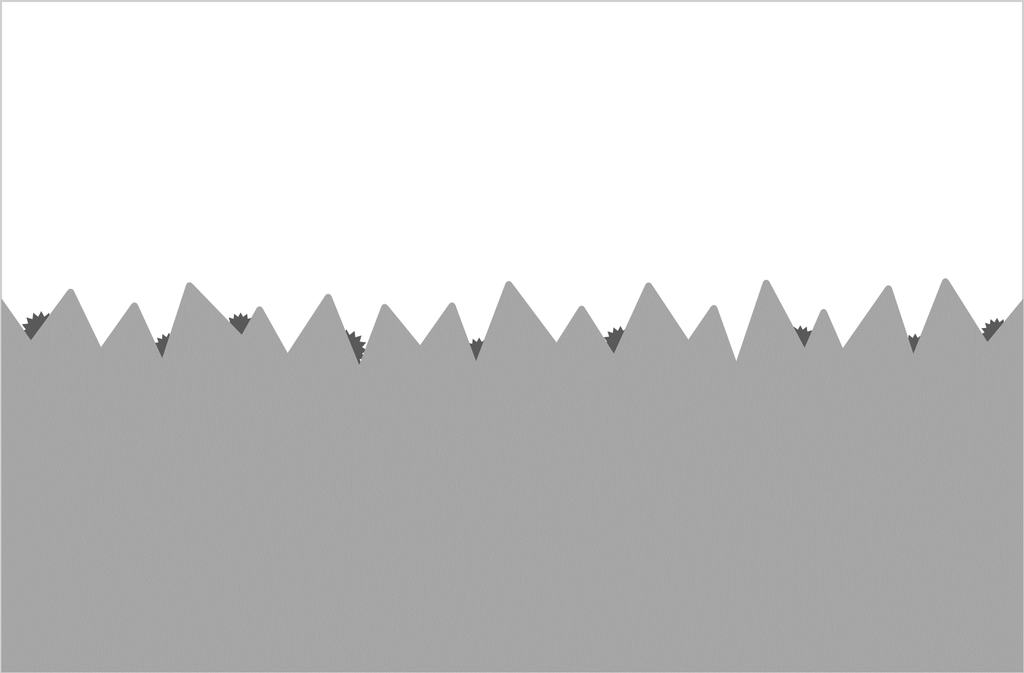

Chemical Polishing:

Chemical polishing is conducted to obtain glossy or matte (pearly or satin) appearances.

Products: ALGLOSS S-200, etc.

Desmutting:

Remove smut resulted from alloying elements such as copper, zinc or silicon in aluminum.

Products: TOP DESMUT N-20, etc.

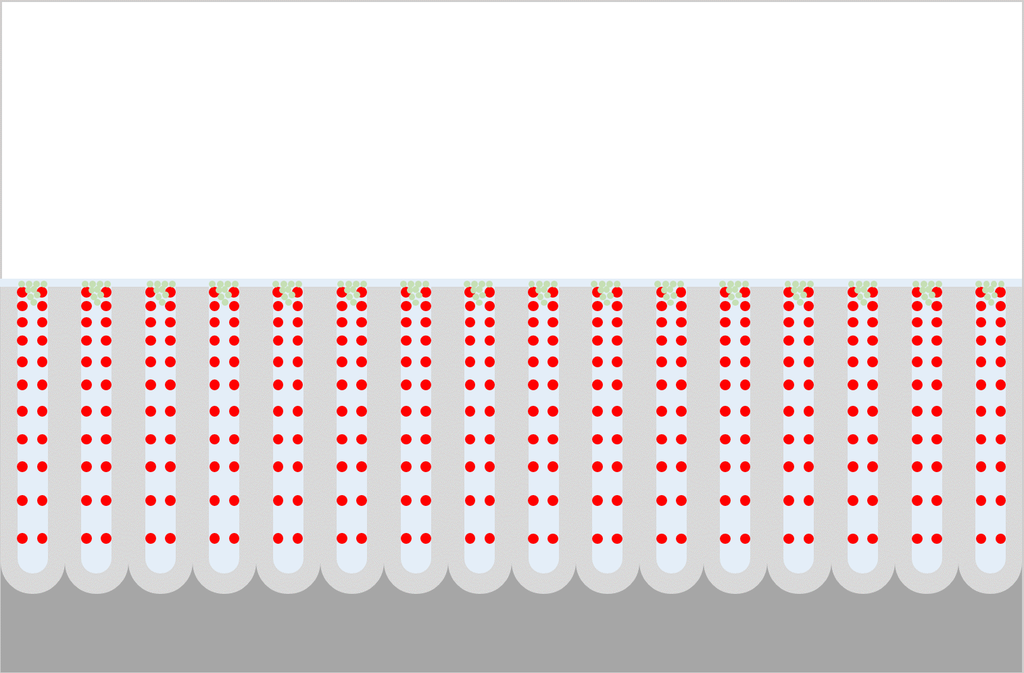

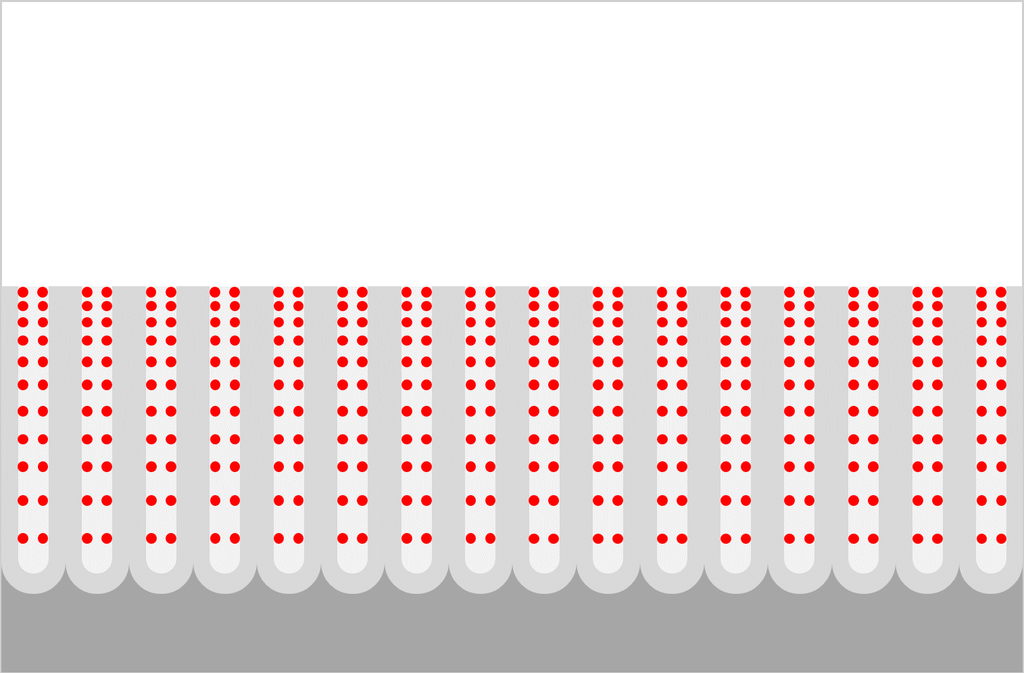

Anodizing:

Generally with sulfuric acid baths, conduct anodizing treatment.

Transparent and porous layers are formed on aluminum, and the oxide films have ultra-micro pores in nanometer size.

Products: ALMIST W, etc.

Surface Conditioning:

Removes the sulfuric acid that remain on the surface and in the micro pores.

Products: TAC SORMAL 244, TAC SORMAL 121, etc.

Dyeing and Coloring:

Immerse aluminum into dyeing solution to make coloring dyes absorbed into micro-pores.

Products: TAC DYESTUFF, TAC STABILIZER, etc.

Sealing:

Oxidized aluminum is hydrated at the insides of ultra-micro pores, also nickel hydroxide deposits near the top of the pores. By these reactions, dyes are stuffed into holes and corrosion resistance is enhanced.

Products: TOP SEAL DX-500, TOP SEAL E-125, etc.